Applications

Helping the most energy intensive industries decarbonize.

Industrial heat is a fundamental component across various sectors, enabling the transformation of raw materials into finished products. It plays a pivotal role in processes such as smelting, refining, drying, and chemical synthesis. However, achieving the high temperatures required for certain applications often involves burning fuels.

NOC Energy’s technology is specifically engineered to help these industries meet their process conditions by delivering thermal energy in the form of a stream of air or an inert, oxidizing or reducing gas at the adequate temperature, all while eliminating carbon emissions.

NOC Technology seamlessly integrates with existing infrastructure, speeding up the transition to a cleaner production.

Applications

Helping the most energy intensive industries decarbonize.

Industrial heat is a fundamental component across various sectors, enabling the transformation of raw materials into finished products. It plays a pivotal role in processes such as smelting, refining, drying, and chemical synthesis. However, achieving the high temperatures required for certain applications often involves burning fuels.

NOC Energy’s technology is specifically engineered to help these industries meet their process conditions by delivering thermal energy in the form of a stream of air or an inert, oxidizing or reducing gas at the adequate temperature, all while eliminating carbon emissions.

NOC Technology seamlessly integrates with existing infrastructure, speeding up the transition to a cleaner production.

Clinker formation

In cement manufacturing, several processes can be decarbonized. The drying of the slurries and other raw materials, for instance, and the clinker production which requires temperatures of up to 1450 °C.

NOC Energy Technology can provide process heat for drying of raw materials, and can recycle waste heat from for example, the cooling of the cement that comes out of the clinker, and can provide a significant portion of the clinker heat requirements, helping this industry cut almost entirely its CO2 emissions.

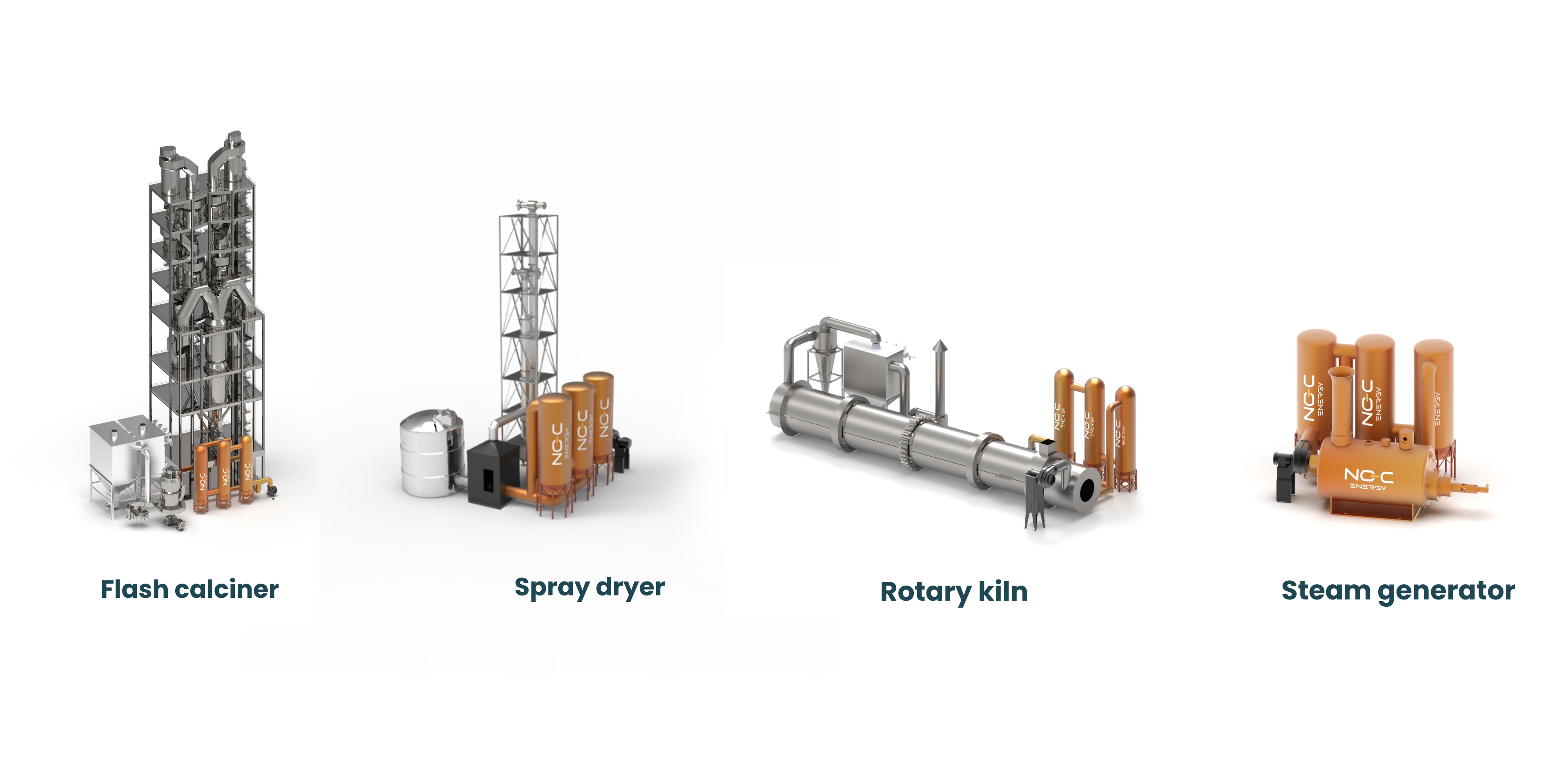

Drying

NOC Energy Technology can provide a steady stream of hot air than can integrate into existing drum dryers for instance, and since there are no combustion gases, it can be made a closed loop system to increase energy efficiency.

Food processing, pharmaceuticals, mineral processing, paint curing, ink drying, textiles, agriculture, woodworking, pulp an paper and many other industries need drying processes making it a prime application to our technology.

Pyrolisis

This process is used to produce ethylene, hydrocarbons from petroleum (steam cracking). The process is also applied in the production of hydrogen from methane in presence of steam to remove solid carbon, (methane pyrolysis or steam methane reforming).

NOC Energy Technology can seamlessly integrate with pyrolisis processes providing the thermal energy required in the form of an inert hot gas at over 600 °C (1100 °).

Power generation

The great advantage of this application is that it allows arbitrage in markets where combined cycle peaker plants are burning natural gas to provide fast response during peak electricity consumption hours.

With NOC Energy Technology, the peaker plants in the electricity markets can operate by charging the HTGG units during low-cost electricity hours to later dispatch the energy at the peak electricity periods, all this without burning any type of fuels.

Smelting and metal refining

NOC Energy Technology can provide the required energy through a stream of hot gas, recirculating CO and separating the CO2, making the process even carbon negative.

Curing

NOC Energy Technology can integrate into curing ovens or continuous curing processes without needing to change existing infrastructure, reducing up to 100% of CO2 emissions. Used for instance in the production of boats, GRP pipes, etc.

Distillation

NOC Energy Technology can provide a stream of hot gas that enters the existing furnace replacing the fossil fuels burning reducing up to 100% the CO2 emissions.

Calcination

NOC Energy High temperature gas generator is ready to use in these industries providing them with the thermal energy needed with no carbon emissions.

Steam Generation

With NOC Energy's technology, it is possible to produce 24/7 high quality steam using intermittent renewable energy.

Plastics Processing

Producing polymers is energy intensive: Polymerization, compounding, chemical or physical recycling are exalpes of such processes. Transforming plastics into products is also energy intensive, for example, injection or rotational molding, blowing, extrusion and thermal forming all require great amounts og heat.

Usually gas burners are used to provide the heat. NOC Energy HTGG can seamlessly replace the gas burners decarbonizing up to 100% the process.

High-temperature kilns

With NOC Energy's technology, it is possible to produce 24/7 high quality steam using intermittent renewable energy.

High-temperature chemical reactions