Newsletter |

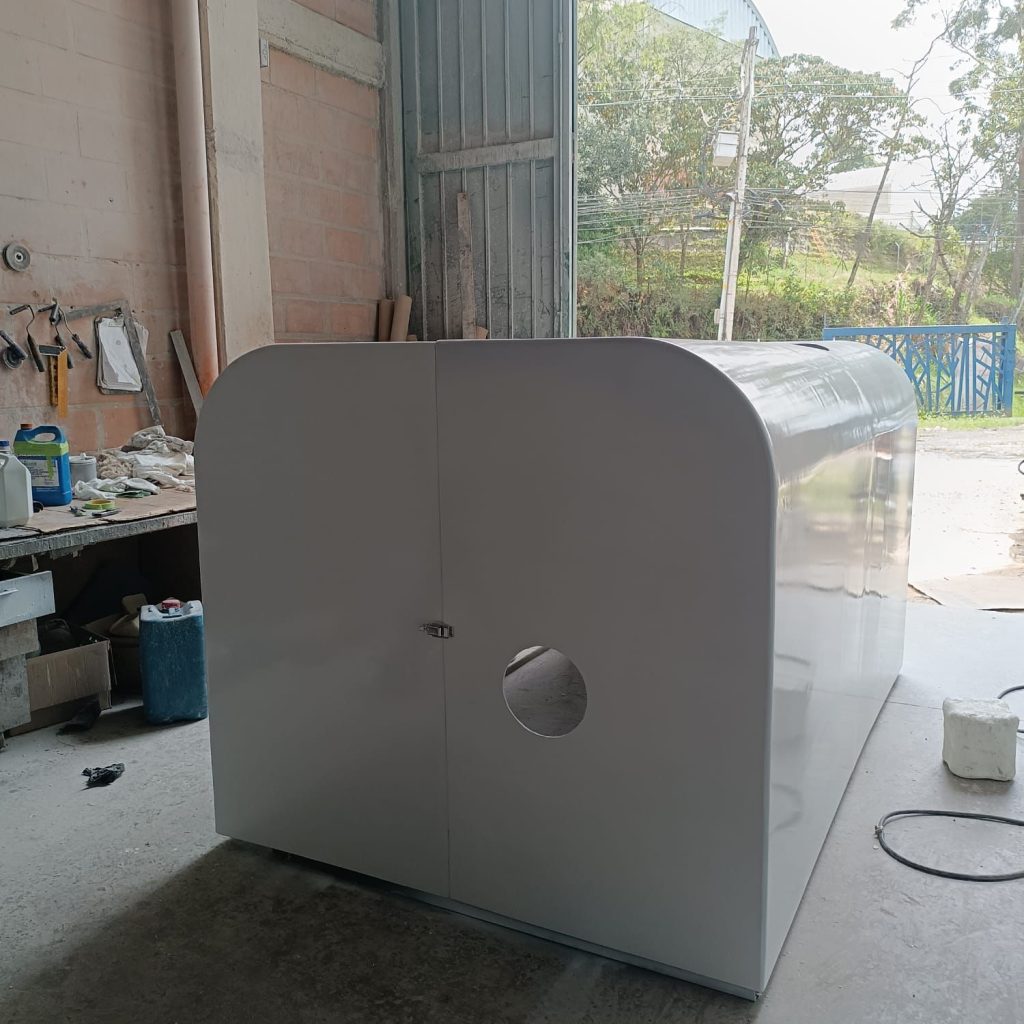

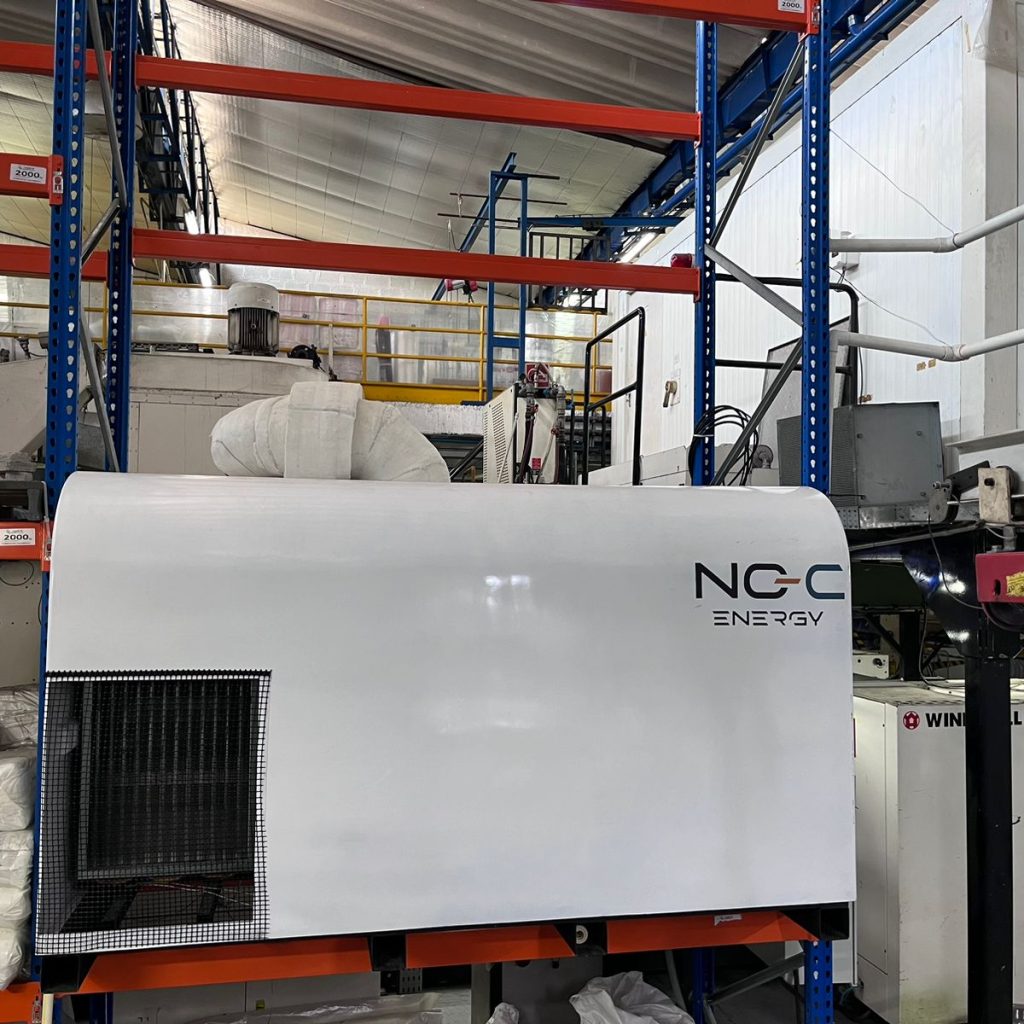

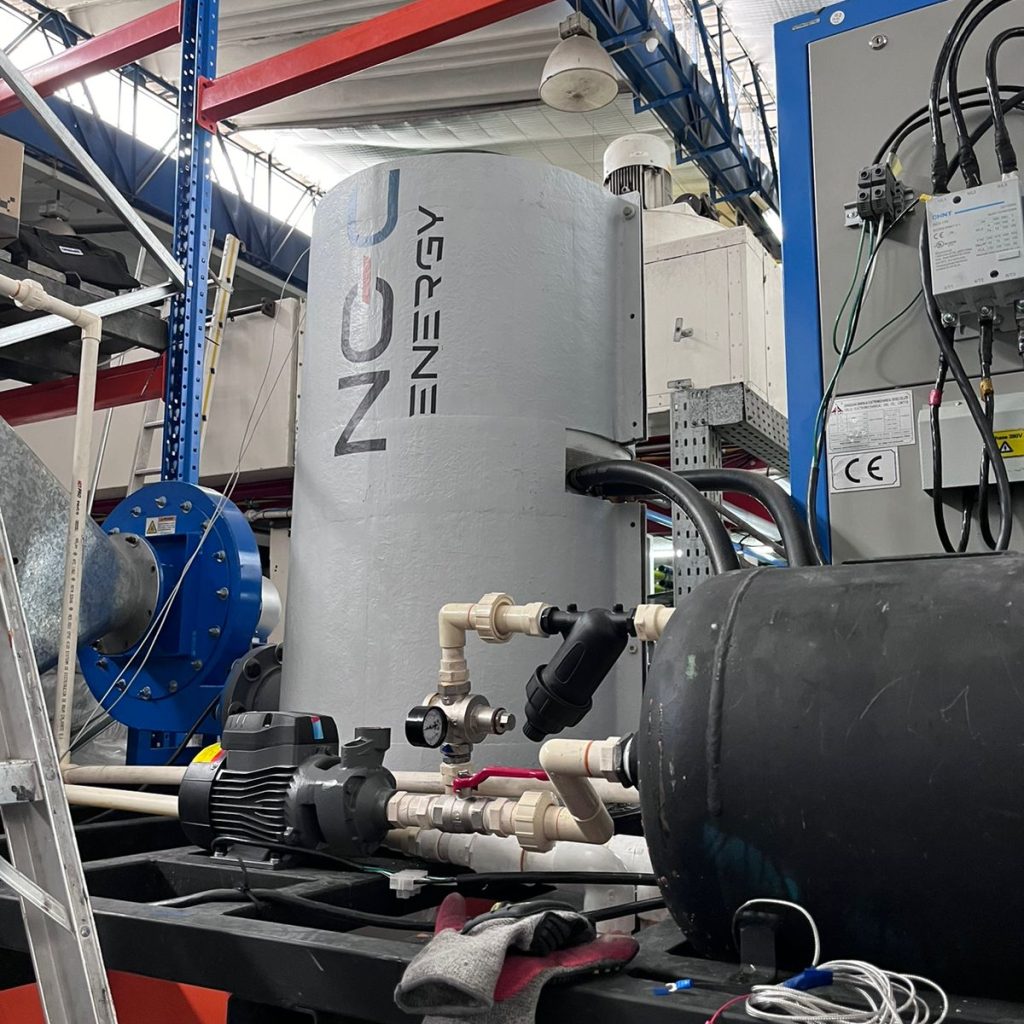

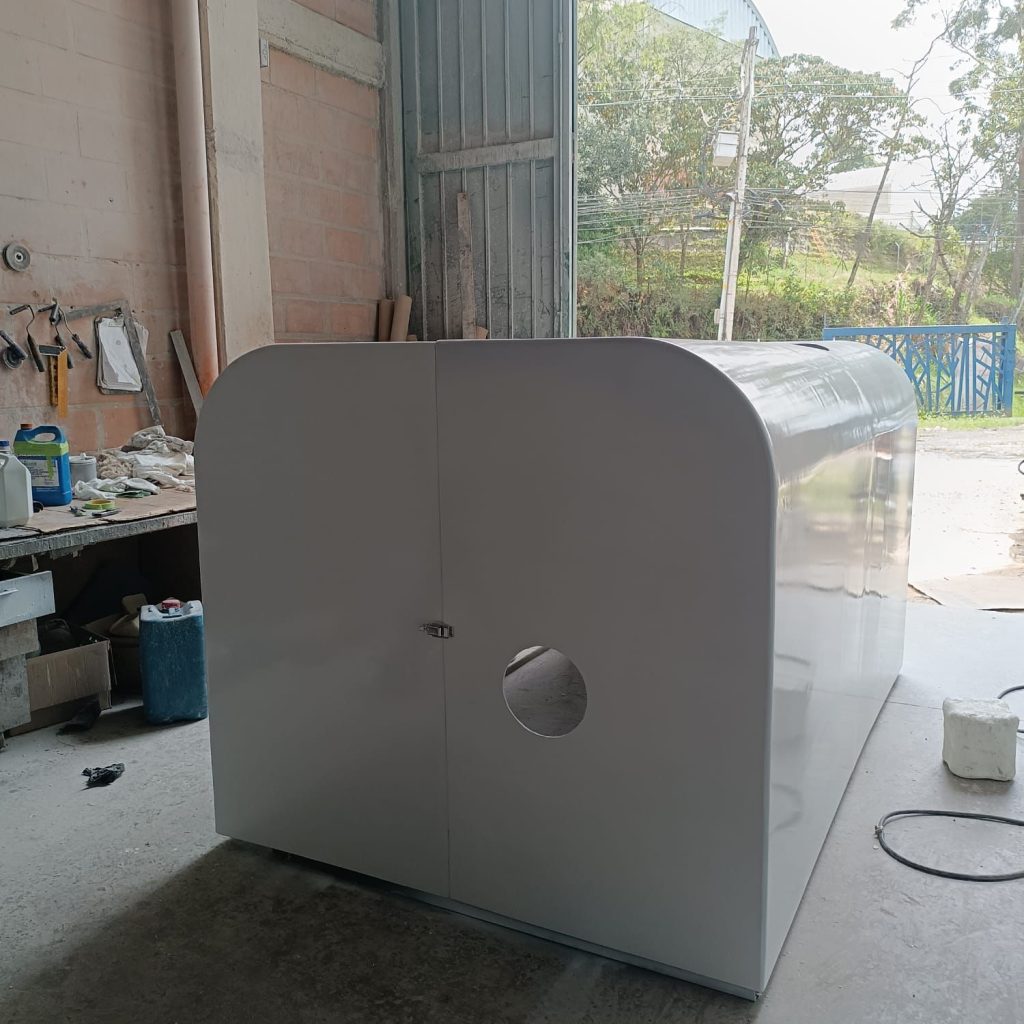

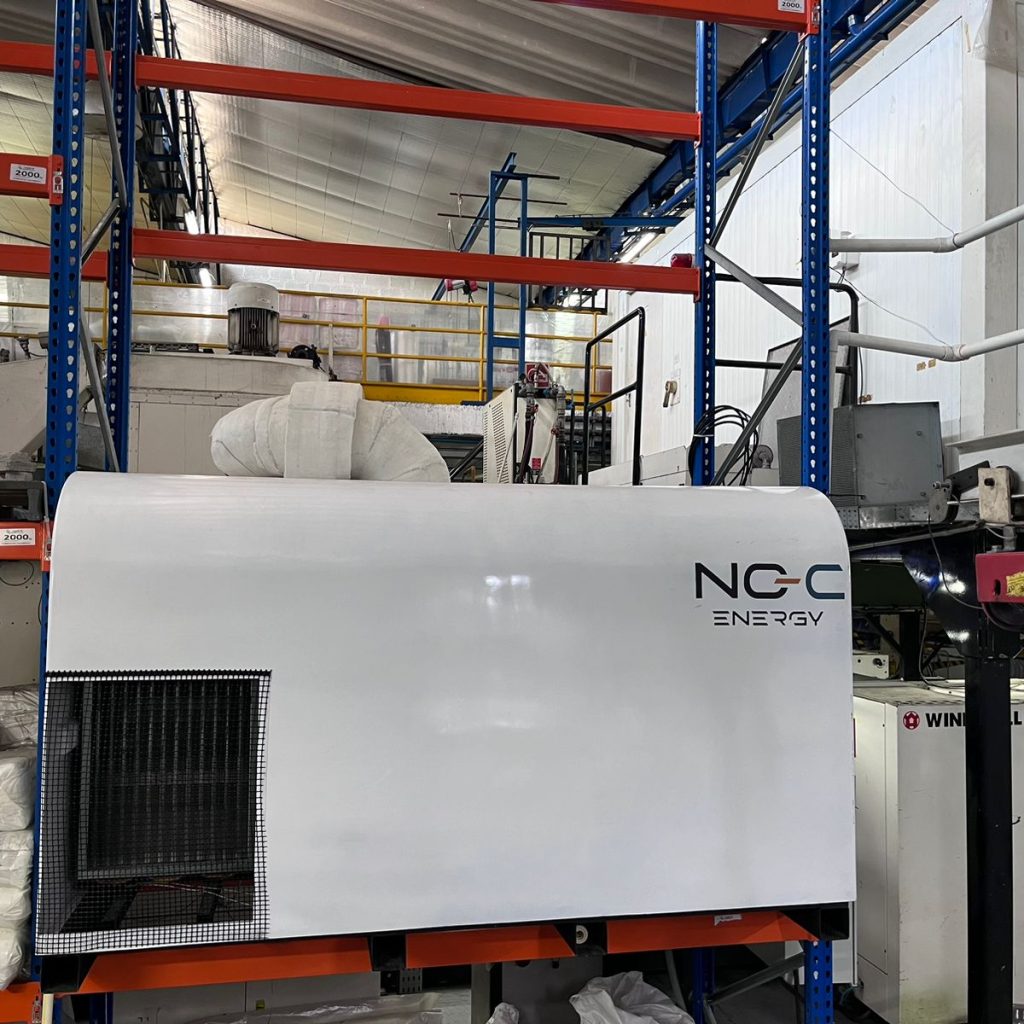

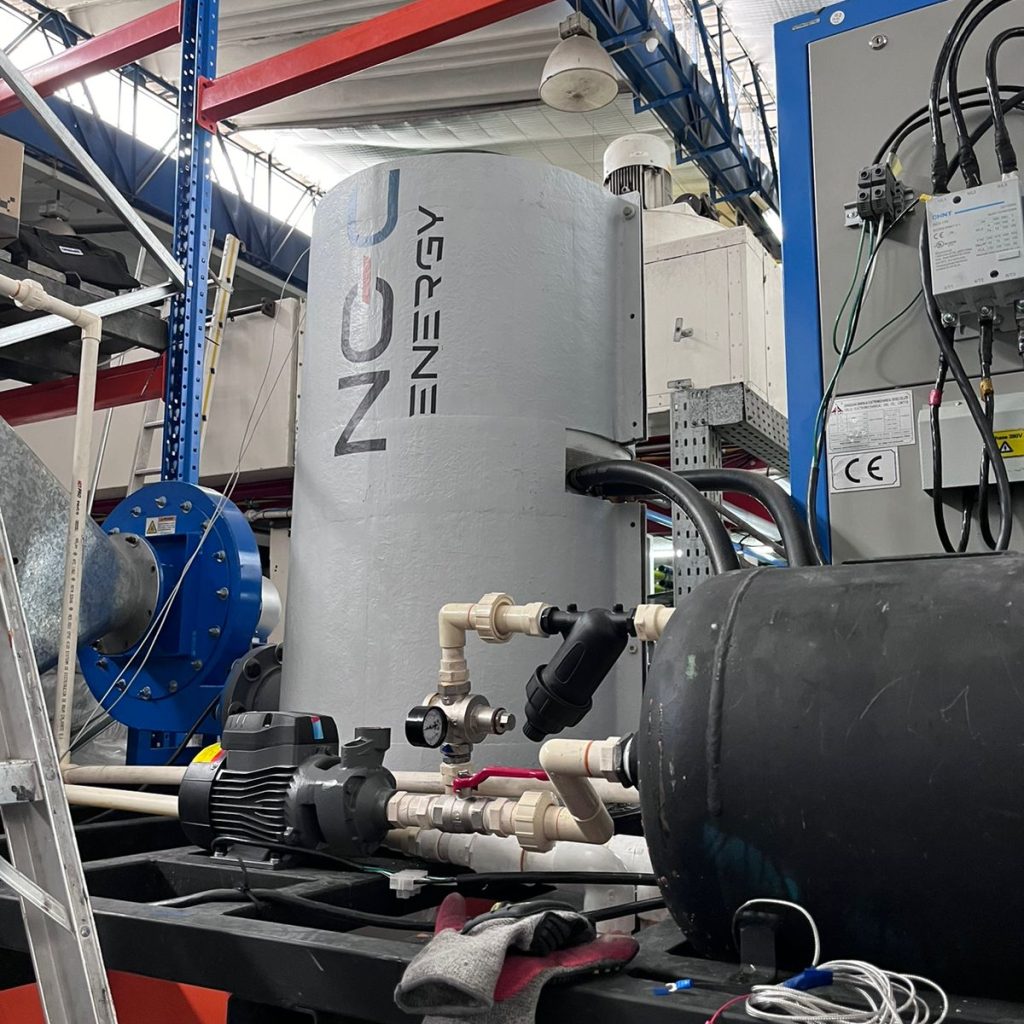

Commissioning of the first industrial pilot.

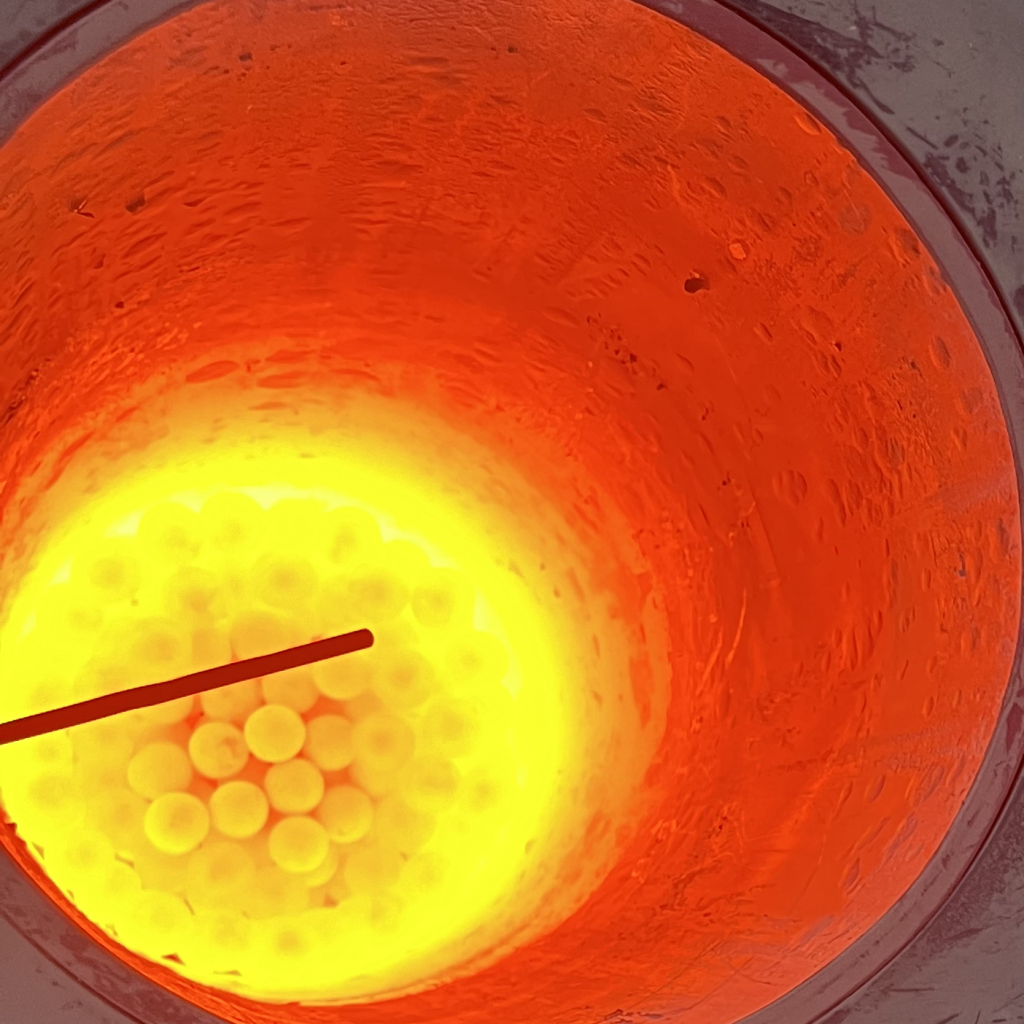

We are proud to announce the successful commissioning of our first industrial pilot – a hot air generator now installed in a customer facility for a drying process. This milestone represents a significant advancement in our technology and product development, demonstrating both its efficiency and operational performance.

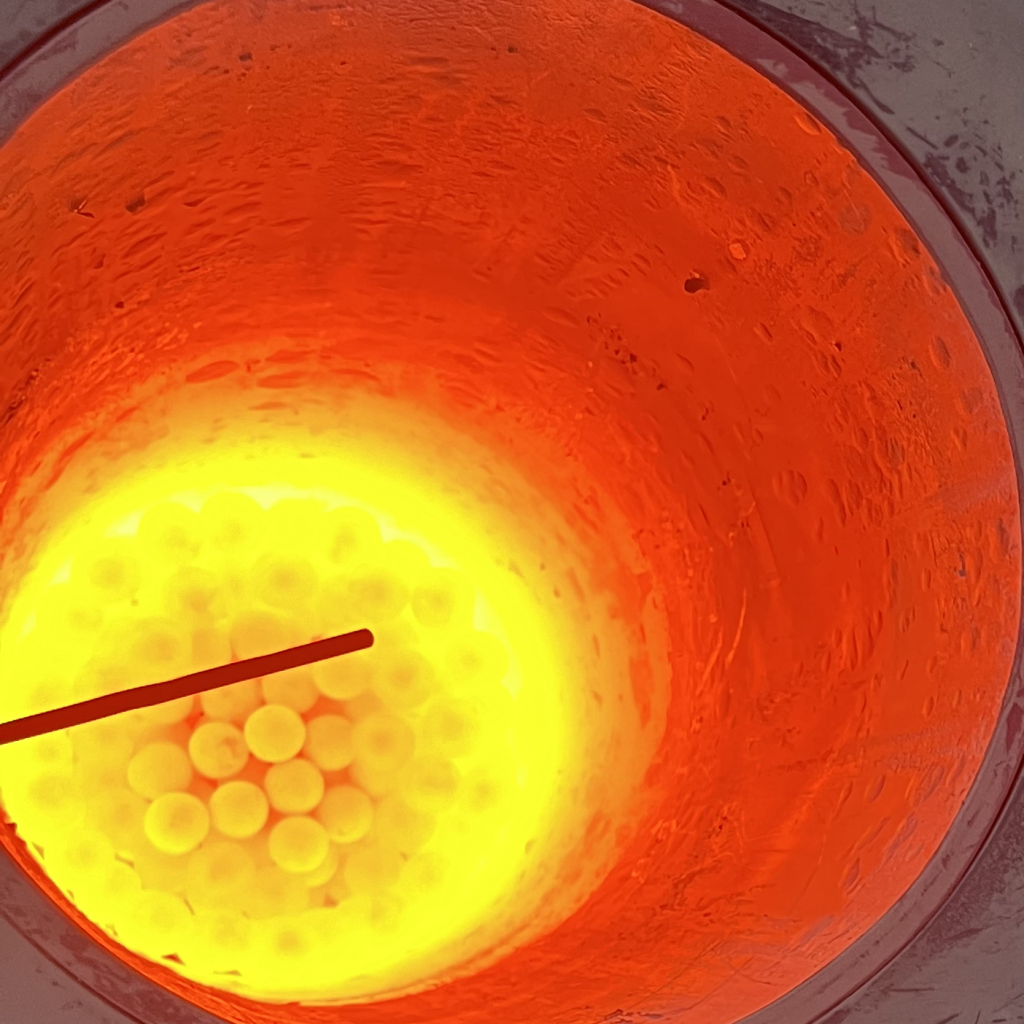

We have successfully met the objectives set for this pilot, demonstrating our ability to achieve temperatures exceeding 1100°C. This full-fledged industrial pilot delivers continuous heat at temperatures above 700°C. proving our system scales-up both in thermal and electrical domains.

With our successful scale-up, we are gaining the confidence of potential customers, allowing them to move forward with commercial pilot opportunities in applications in processes like drying, curing, pyrolysis and steam generation across industries such as mining, minerals and metals, chemicals and refining.

In this regard, we are currently developing other industrial projects focused on the above mentioned industries in processes requiring temperatures ranging from 600 °C to 1300 °C.

Strategic Partnerships and Collaborations.

Greentown Labs. We have been admitted to Greentown Labs in Houston (GTL), the largest climate tech startup incubator in the US, providing resources, community, and mentorship to help clean energy and sustainability-focused entrepreneurs scale their companies. Greentown hosts more than 80 startups and is supported by more than 100 sponsors, amongst which are the largest energy and technology companies in the world. Through GTL we are actively engaging the sponsors to look for pilot and commercial opportunities.

Market Outlook.

The electrification of industrial processes is set to accelerate in 2024 and beyond, driven by a confluence of market and regulatory forces:

- The increasing exposure to spot LNG prices in Europe has highlighted the need for more stable and predictable energy sources. This economic environment is prompting industries to move away from gas and invest in electrification, a solution that has been used in various industries for over a century.

- The growing incorporation of renewables into power grids is also playing a crucial role. As the cost

of renewable energy technologies, such as wind and solar, continues to decline, the annual average grid price during the lowest 4 to 6 hours of the day is becoming increasingly competitive with natural gas. - Additionally, policymakers are enacting stricter regulations to compel industries to reduce their

carbon emissions. For instance, the price of carbon under the European Emissions Trading System (ETS) is currently above €100 per ton of CO2 and is expected to rise further.

These three long-term forces are shaping a future where decarbonization becomes not only beneficial for business but also cost saving in production. Companies accustomed to long-term planning can anticipate this shift and evaluate their pathways (including hydrogen and carbon capture and storage) finding that electrification of industrial heat stands out as a powerful tool for decarbonization with the potential to create significant societal impact immediately.

At NOC, we are driving the development of decarbonization technologies to provide maximum flexibility with electrification. Our product platform enables us to customize energy storage solutions to achieve the lowest cost of heat for our customers. Our design ensures that various applications can be addressed seamlessly without reconfiguring the product, with scalability in mind built into its development.

The convergence of these factors with NOC solution creates a robust value proposition and a market opportunity for industries looking to enhance sustainability and long-term resilience. We appreciate your continued support and belief in our vision. We look forward to sharing more updates as we achieve our next set of goals.

Best regards,

Carlos Ceballos,

CEO, NOC Energy

Newsletter |

Commissioning of the first industrial pilot.

We are proud to announce the successful commissioning of our first industrial pilot – a hot air generator now installed in a customer facility for a drying process. This milestone represents a significant advancement in our technology and product development, demonstrating both its efficiency and operational performance.

We have successfully met the objectives set for this pilot, demonstrating our ability to achieve temperatures exceeding 1100°C. This full-fledged industrial pilot delivers continuous heat at temperatures above 700°C. proving our system scales-up both in thermal and electrical domains.

With our successful scale-up, we are gaining the confidence of potential customers, allowing them to move forward with commercial pilot opportunities in applications in processes like drying, curing, pyrolysis and steam generation across industries such as mining, minerals and metals, chemicals and refining.

In this regard, we are currently developing other industrial projects focused on the above mentioned industries in processes requiring temperatures ranging from 600 °C to 1300 °C.

Strategic Partnerships and Collaborations.

Greentown Labs. We have been admitted to Greentown Labs in Houston (GTL), the largest climate tech startup incubator in the US, providing resources, community, and mentorship to help clean energy and sustainability-focused entrepreneurs scale their companies. Greentown hosts more than 80 startups and is supported by more than 100 sponsors, amongst which are the largest energy and technology companies in the world. Through GTL we are actively engaging the sponsors to look for pilot and commercial opportunities.

Market Outlook.

The electrification of industrial processes is set to accelerate in 2024 and beyond, driven by a confluence of market and regulatory forces:

- The increasing exposure to spot LNG prices in Europe has highlighted the need for more stable and predictable energy sources. This economic environment is prompting industries to move away from gas and invest in electrification, a solution that has been used in various industries for over a century.

- The growing incorporation of renewables into power grids is also playing a crucial role. As the cost

of renewable energy technologies, such as wind and solar, continues to decline, the annual average grid price during the lowest 4 to 6 hours of the day is becoming increasingly competitive with natural gas. - Additionally, policymakers are enacting stricter regulations to compel industries to reduce their

carbon emissions. For instance, the price of carbon under the European Emissions Trading System (ETS) is currently above €100 per ton of CO2 and is expected to rise further.

These three long-term forces are shaping a future where decarbonization becomes not only beneficial for business but also cost saving in production. Companies accustomed to long-term planning can anticipate this shift and evaluate their pathways (including hydrogen and carbon capture and storage) finding that electrification of industrial heat stands out as a powerful tool for decarbonization with the potential to create significant societal impact immediately.

At NOC, we are driving the development of decarbonization technologies to provide maximum flexibility with electrification. Our product platform enables us to customize energy storage solutions to achieve the lowest cost of heat for our customers. Our design ensures that various applications can be addressed seamlessly without reconfiguring the product, with scalability in mind built into its development.

The convergence of these factors with NOC solution creates a robust value proposition and a market opportunity for industries looking to enhance sustainability and long-term resilience. We appreciate your continued support and belief in our vision. We look forward to sharing more updates as we achieve our next set of goals.

Best regards,

Carlos Ceballos,

CEO, NOC Energy